|

For many years, I have had Italeri’s monster C-130E kit sitting in my stash

just waiting to be built. With a kit of this size it was crying out for

something a bit more than just “a build”…it needed some life, and after

reading an old FineScale Modeler magazine for the umpteenth time, I decided

to try my hand at adding fibre optics and LEDs. Initially all I could fine

in the LED department were 5 mm lights at Radio Shack and with the space in

the wing tips being very limited, they would not do. I did find some 3 mm

LEDs at a electronic supply store in Langley, BC but they were not very

bright so the lighting system was put on the back burner for a while so that

I could start with re-scribing all of the panel lines on this hugh piece of

plastic. |

|

|

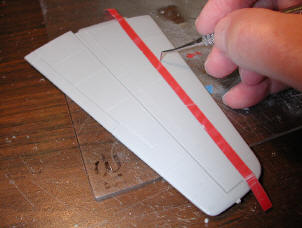

I started

with the stabilizer, a roll of Dymo labelling tape and a dental pick which I

sharpened to remove a fine “curl” of plastic. Three passes were all that it

took to get a very fine panel line. |

|

I next taped the fuselage halves together then started scribing the miles of

panel lines. There were a few “OOPS” along the way but eventually it turned

out quite well…for the first truly big re-scribing job. There were some

interesting shapes that needed special attention; the biggest being the wing

root fairing on the fuselage. |

|

|

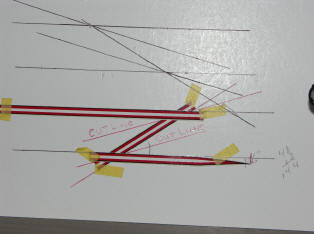

The wing

root template was copied from the raised panel lines using thin paper and a

soft pencil, then transferred to .020 plastic sheet. The centre was

removed, sanded smooth then taped to the fuselage and the fairing scribed

into the plastic. Both sides were done by flipping the template. |

|

The wings and vertical tail were re-scribed and when every panel line on the

model was given the treatment, all components were sanded with 400 wet sand

paper then washed with liquid dish soap and an old tooth brush. The model

sat under my model table for over a year after I had put in about 100 hours

with the panel line nonsense and occasionally I would try connecting LEDs,

variable resistors and other components. Initially I had intended that the

wings would be removable and to this end, I used square brass tubing for

centre section carry-through and wing spars. |

|

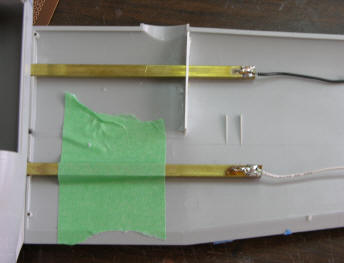

A template

of the wing end root was made using .020” plastic card and the tubing

cut-outs were removed. A false wing rib was added outboard of the inner

engine nacelles. The LEDs were wired to the brass spars and these were then

epoxied into the wings. Trying to figure all of this out was pretty time

consuming and over time, newer LEDs were produced which gave out much more

light over a wider area. These were substituted for the original LEDs.

I then added Milliput epoxy in the wings at the root for strength..not

shown here. Once the spars had set up they were set aside while the

electronics were taken care of. |

|

The Hercules has two anti-collision lights, one on the top of the vertical

tail and one on the bottom of the fuselage aft of the nose gear rear door.

To make these realistic I used two Superbright Red LEDs wired to a socket

which would take an LM3909 chip. Using the wiring diagram in FSM, I wired

up the socket, plugged in the chip and applied power to the LED circuit…and

we had flashers! The LED was epoxied into the top of the fin and the wires

which would eventually provide power were brought out through the end of the

dorsal fin…where they would eventually be routed through the top of the

fuselage. |

|

|

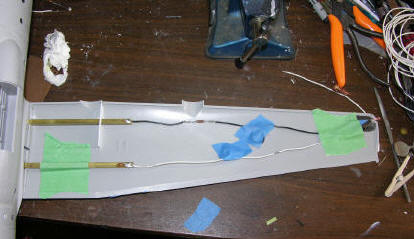

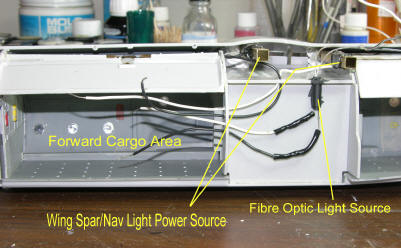

Now it was

time to tackle the fuselage. The wiring was inserted in the wing centre

section and the two brass carry-throughs were used for the Positive and

Negative contacts for the wings. I added a Super Bright White Led in the

left side of the fuselage over the wheel well and routed the wires through

the bulkhead into the forward cargo area. |

|

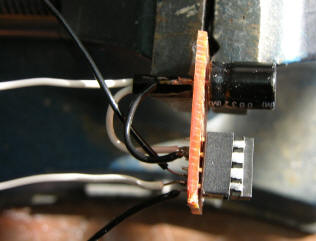

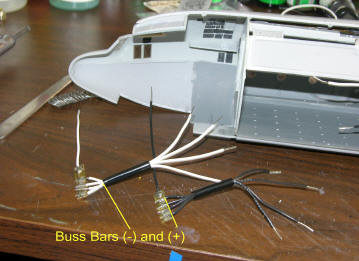

I needed a secure system for the power supply so I cut

two strips of brass, added the white negative wires to one and the black

positive wires to the other. I then had the cockpit lighting to worry about

and not having any photos of a Hercules instrument panel with lights, I

decided to use only one Super Bright White LED to the top of the cockpit

bulkhead to light the entire cockpit.

The nav lights in the tail are made from fibre optics

and these plus the cargo bay overhead lights, also fibre optics, were

plugged into a piece of plastic tubing which had a SB White LED in the other

end. The tubing was then painted black for maximum light retention.

|

|

|

|

|

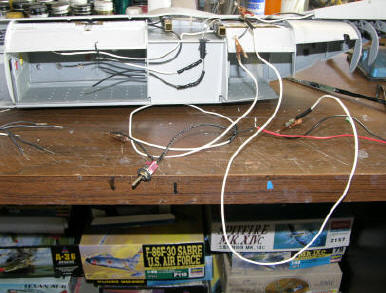

The fuselage was now taped together, the wings and vertical tail added and

the power was hooked up. Testing for lighting serviceability must be

carried out frequently before the whole thing is assembled. |

|

|

|

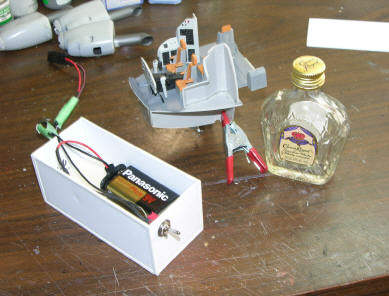

The fibre optic bundle was tested and then tucked into the fuselage/wing

centre section and epoxied in place. I used heat-shrink tubing to keep the

fibre bundle together. The power supply, a 9 volt battery, was housed in a

plastic “crate” which I made out of Sheet and strip Evergreen plastic. The

On/Off switch was wired into the end of the box which was painted with

Humbrol “WOOD” acrylic using a stiff bristled brush. |

|

I found

numerous very different cockpit photos of the Hercules and there were as

many versions as there were aircraft. With the help of ARC members and my

supply of photos, I detailed the instrument panels, the overhead and side

panels and added photo-etched seat belts, and placed a coloured map on the

Navigators desk. To cover the void behind the instrument panel, I cut a

piece of aluminum foil, embossed it with a diamond pattern stitching using a

toothpick, painted it flat black and super glued it in place. Because of a

lack of cockpit lighting photos, I installed a Super Bright White LED near

the top of the cockpit bulkhead and wired it into the buss bars. This gave

off sufficient light to illuminate the cockpit without too much glare. |

|

|

|

It was now time to close things up. The vertical tail was glued to the

right side of the fuselage and the wiring fished through to the buss bars

and flasher unit. The square brass carry thoughs were secured with Milliput,

the kit supplied spar glued in place and the fuselage taped together. The

wings were slid into place and quickly taped into position and the whole

thing set aside for 24 hours to give the Milliput time to cure. |

|

The wings were removed and the fuselage reopened for

final wiring…and testing. With everything working properly, the fuselage

was glued together, the fin glued to the left side of the fuselage and the

wings glued into position. The stabilizors were glued into position and

everything squared up as the glue cured. I installed the prefinished

landing gear into the wells which had been detailed and painted.

Windows in the fuselage were masked, Kleenex stuffed

into all openings and the monster was ready to paint. |

|

|

|

I touched up the panel lines over the top of the fuselage and wing roots

then sprayed the walkway areas flat grey using Polly Scale. I then masked

over the walkways and sprayed the top with Model Master Gloss White…over a

coat of Polly Scale White. I then masked over the white and masked the wing

tips and horizontal tail for the Model Master Guards Red. |

All of the

prepainted areas were masked and then I sprayed the bare areas with Alclad

II Gloss Black Primer. Two days later, I sprayed the Alclad II Polished

Aluminum and when the tapes came off, so did the paint…lots of bare plastic

showing. After sanding and re-spraying the painting was finished…or so I

thought! |

|

|

|

While waiting for the paint to dry, I painted the props using Polly Scale

and when dry, I used strips of decal to complete the warning stripes on the

tips. This gives a much better finish than trying to mask and paint. |

The

fuselage flash line was from an old set of Canforce Decals and had to be cut

to size. I made a template on gloss white card, taped the decal in place

and cut them to length. The pieces fit perfectly when applied to the model. |

|

|

|

Some of the decals; the tail and underwing numbers along with the “Last Two”

on the nose, and the black drop-shadow outline on the “ROYAL CANADIAN AIR

FORCE” red lettering were made using Coreldraw 10 and printed on a HP

laserjet 4P. |

The cargo

bay ramp and doors were glued into position and brass tubing used for the

ramp braces. The “cargo” was installed and after adding the gear doors and

antennae the monster was finished…except for the paint under the windshield

that came off while trying to get rid of the Bare Metal Foil goo. Touch-ups

were made but not to my satisfaction…maybe another time in another life….! |

|