|

|

|

In June 1996, I bought myself a birthday present, a

1972 Grumman American AA1A and over the past few years, I have restored

the aircraft to its present condition and then decided that I needed a

model of my little yellow bird. Bragging rights you know! |

|

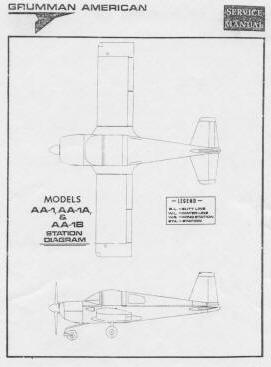

I scanned the top and side view of the aircraft

from my maintenance manual and confirmed the measurements against the

1:1 scale bird. This was then imported into Coreldraw and then scaled

to 1:32 using this program. These views were then printed out and used

to make parts templates which were then transferred onto .040” Evergreen

sheet styrene for the majority of the model.

|

|

|

|

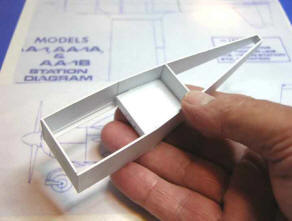

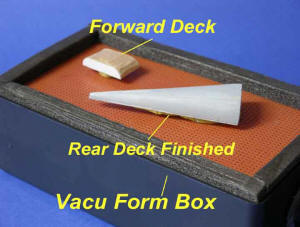

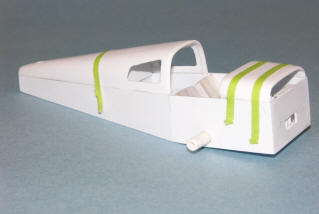

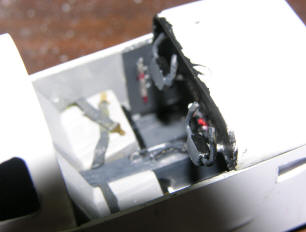

The fuselage is a basic box shown above with the

baggage compartment floor installed. I carved the top decks from balsa

and then vacuformed them from .040” sheet plastic. As in any new

scratch-build project, these parts were built more then twice until they

were what I wanted.

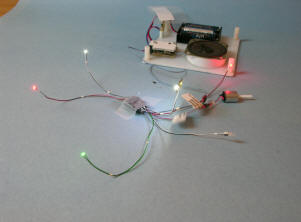

While thinking about this project, I decided to go

all the way and contacted Clyde Sasaki at Dynamic Scale Models, an

electronics firm in Portland, OR. I wanted a model with full lighting;

Navigation lights, anti-collision lights, pulse-lite on the nose,

lighted instruments and of course an electric motor to spin the

prop…with sound. |

|

|

|

When the electronics package arrived, I made up the

instrument panel from three layers of .020” plastic with instrument

decals from Mike Grant. The back side of the rear piece was painted

flat white to diffuse the illumination from the miniature LEDs. The

panel has every control, switch, instrument and circuit breaker just

like the big toy. |

|

|

|

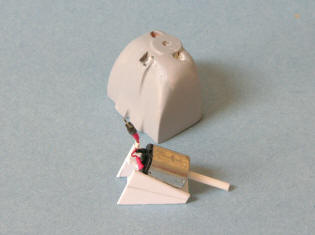

I test fitted the vacuformed top sections and when

satisfied, cut out the rear windows then I went to work to make up the

tail section. This was formed from layered pieces of .040” plastic and

when the airfoil shape was achieved, after a lot of filing and sanding,

I cut off the control surfaces. The vertical stabilizer was made with a

narrow channel up through the centre necessary for the LED

anti-collision light. |

|

|

|

I dug into the spares box for a spinner and prop

and seats and surprisingly enough these came from a partial Pitts S2B

kit that I had on hand…and they fit! I did have to reshape and shorten

the prop blades but this was a minor operation.

The landing gear came from the same source, the

destroyed Pitts S2S Bulldog. Very little modification was required

here. |

|

|

|

The wings were a composite of carved balsa core and

.015” sheet plastic with a plastic tube inserted into the bottom of the

wing for the LED nav lights. The 1:1 scale aircraft has a tubular spar

and this was incorporated into the model. This made the wing assembly

much easier later on. The wing root fairing is a build up of sheet

plastic which was finished after numerous attempts to get it right.

The ailerons and flaps were constructed from

plastic sheet and tube as per the original. |

|

|

|

Using the electric motor supplied by

Dynamicscalemodels.com and the side view of the fuselage I determined

the location of the motor mount and then formed it from .040” plastic.

It was then time to carve a mold from balsa for the cowling. The full

size cowling is made up from three pieces, top, bottom and nose bowl.

The balsa mold was carved in one piece then carefully cut apart along

the full size panel lines. After about five tries, I had a good cowling

vacformed from .040” plastic. The nose bowl and bottom piece were glued

together and the cowling top was made removable by making up a

tongue-and-groove as per the original, along the panel line.

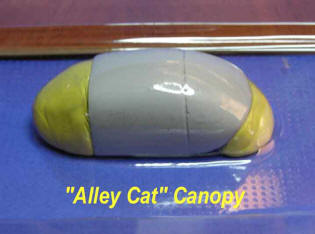

I also carved a balsa mold for the canopy but this

was a very frustrating exercise as I made more than 10 copies before

getting a good one. I tried a number of types of plastic but finally

settled on .030” PETG obtained from a local plastics shop. I have

enough of this product to make hundreds of canopies! |

|

|

|

The centre console between the seats would hide the

power wires to the cowling and the LED navigation lights and this plus

the seats were installed after the interior was painted and the IC chip

was installed in the baggage area behind the seats and the wires were

routed to the proper locations. I installed the instrument panel, glare

shield and fuselage top followed by the vertical tail, horizontal tail

and tail cone which housed the fibre optic navigation light. |

|

|

|

The navigation light covers on the full size

aircraft were vacformed but the small size of the model required

something different. I rough cut pieces of Plexiglas for the lens

covers then shaped them with a sanding drum in my Dremel tool. They

were filed, sanded and polished, the latter using Novus #3 Plastic

Polish and a cotton polishing disk in the Dremel. When they were

finished I set them aside until final assembly. |

|

|

|

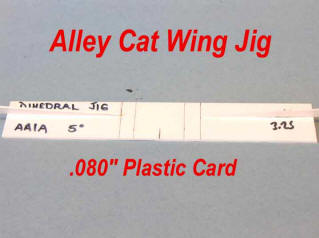

I made a wing jig from .080” plastic to ensure the

correct dihedral then assembled the wings and fuselage with plenty of

tape. The model was then taped to the jig and glued together. During

the assembly, I could have used another set of hands to hold the model

while I fished the LEDs through the wings.

The landing gear was installed along with cowling,

fuel caps, stall strips on the leading edges of the wings as well as the

navigation light covers on the wing tips. |

|

|

|

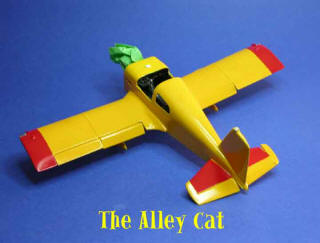

The model was then given one last test of the

electrics before going to the paint shop. With everything working

perfectly, I primed the model with Mr Surfacer 500 and sanded back down

to bare plastic while looking for defects. When satisfied, I shot the

yellow using Model Master Chrome Yellow enamel thinned with lacquer

thinners. |

|

|

|

With the yellow now thoroughly dry, I masked it off

and applied the Model Master Guards Red enamel and the Flat Black

anti-glare panel on the cowling. The decals were supplied by the BIG

spares box and fortunately all were scaled correctly for the size of the

model. Because of the relatively small size of both the 1:1 scale

aircraft and the 1:32 scale model, it was important to get the decals in

proper proportions to fit each one and I used Patrick Martin’s book,

Royal Canadian Air Force Aircraft, Finish and Markings, 1945-1968 as my

prime reference.

The final bits; the VHF Com, VOR or and ELT

antennae along with the windshield, canopy and rear windows were then

installed. To find a pilot for the little beast, I dug up one from the

1:32 scale Matchbox Tiger Moth, chopped and channeled him, ground him up

with my Dremel tool and then when he fit into the seat, I painted the

figure, added a David Clarke headset with boom mike and set it aside to

work on the base. |

|

|

|

The power and sound module are under a base made

from 5mm Plexiglas. The power wires run up through a battery cart to

the auxiliary power plug on the right side of the cowling. The cart

with battery and fire extinguisher are all scratch-built and yes the

battery is to scale. The “Snap Off” tool box contains the rare earth

magnet which activates the system when it is placed by the mechanics

right foot. |

|

|

|

The mechanic figure came from the Matchbox Tiger

Moth kit and it was detailed to represent my good friend Werner

Griesbeck who made the 1:1 scale bird such an eye catching example of

his artistry with restorations. And finally a close up of the Dynamic

Duo on start up!

To watch a short

movie of the Alley Cat click here |

|

|

|

| |

|