|

| |

Jim LeRoy's Pitts S2S "Bulldog" Construction

Article

|

1/32 Scale Resin Kit by AirshowModels.com

During the big show at Oshkosh, Brian

Fawcett delivered the new Pitts Bulldog kit items for all to drool over.

The kit is another in the Airshowmodels.com series of colourful aircraft in

1/32 scale. This highly modified Pitts S2S is flown by owner Jim LeRoy on

the air show circuit along with his crew chief “Opus”, the Engish Bulldog.

It is alleged that Opus has been grounded for flying too low to fire

hydrants.

|

|

|

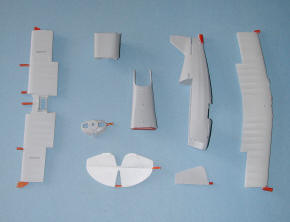

A Review of The Kit

As in the other kits by this new

Canadian company, the majority of the components are cast in a hard resin.

There was some minor amount of flash on the parts that I received but this

was easily removed with a sanding stick. There are a number of parts cast

in brass and there are two photo-etched frets, along with a very

comprehensive decal sheet. Also included are two vacu-formed canopies and

lower fuselage window and a full colour construction manual with plenty of

close-up construction photos to aid in the assembly of this model.

|

|

|

The large photo-etch fret is the same one

used in the Pitts S2B however many of the parts are not used in the Bulldog.

Construction

I began by removing all of the pour stubs

from the components, using a fine toothed razor saw and sanding sticks. Extra

care is taken in removing the stubs from the tail surfaces as they are very

thin. Once all of the parts are cleaned up, they were washed in warm water

using an old toothbrush and liquid dish detergent. This preps the model for

gluing and painting later on.

The lower wing was dry fitted to the

fuselage and with very little additional sanding the fit was perfect. I then

mixed up some 5 minute epoxy and glued the lower wing in position. Next the

horizontal tail and main gear were epoxied in place and while the epoxy was

still in the set up stage I added the cast brass axle struts and the tail wheel

support block was added. Next came the cast brass tail wheel.

The excess epoxy was removed using a Qtip

and Isopropyl alcohol

|

The interior was next with the rear control

column being soldered to the aileron torque tube and this installed in the

fuselage along with the photo-etched heel scuff plates, the edges of which

must be bent up to allow them to fit into the base of the interior. I then

added the throttle quadrant and fuel selector valve. The interior was then

painted light grey with black throttle handle and red fuel valve. There is

a front seat which has the radio cast on the back. The radio is painted and

detailed and the seat glued into the fuselage.

|

|

|

The rear seat was painted flat black,

the seat belts red and a bit of silver detailing before being installed in

the fuselage. I then detailed the instrument panel using decal instruments

from an old Airwaves sheet. At this point the upper fuselage fairing was

glued in place as was the cowling.

The cowling has the front two cylinders

cast in place. These are painted and the nose bowl glued on. Now the

cooling gill was added and any fill required was applied to clean up the

joint lines. |

|

The wings have separate ailerons that

can be positioned to your preference. The rudder is also a separate item.

These were glued in place using CA. The front cabane struts were soldered

together and these and the rear cabane struts were glued into the bottom of

the upper wing.

The model was then given a coat or two

of light grey primer and any imperfections were then cleaned up in

preparation for painting. |

|

Painting

The cockpit, under fuselage window

opening and the cowling openings were stuffed with damp tissue. I used

Micro Mask on the tabs of the interplane struts and in their respective wing

slots. The original aircraft is painted “Dynamite Yellow” and this is

approximated by using Model Master Bright Yellow, part number 2717. The

upper surfaces were given 4 coats of yellow and when dry, I masked off those

areas to remain yellow then used Model Master Gloss Black to complete the

painting.

|

|

|

Decals

Decaling was started by applying the

silver fuselage stripe, followed by the rest of the logo decals. For your

particular model, refer to Jim’s web site at

www.bulldogairshows.com. There are enough sponsor logos to cover a

number of years of operation. Check the photos carefully. The wings were

decaled, again checking for sponsor logos. The decals are very thin but

might require a brushing with Solvaset to get them to adhere properly. I

did have a bit of trouble getting the silver stripe to go under the nose

however by cutting small nicks in the bottom of the stripe I was able to

convince it to behave.

Final Assembly

I decided that this one would have the

canopy open so I carefully cut the windshield from the rest of the bubble

and glued it in place. The windshield does not have framing over the bow so

I merely scribed along the front side of the recessed frame line. The

fuselage gas caps were added ahead of the windshield.

The upper wing was next. I used epoxy

again in the interplane strut slots (after removing the masking) and the

cabane strut holes on the top fuselage fairing. The wing was held in place,

the interplane struts snapped into the slots and the whole thing held in

alignment until the epoxy had cured…5 minutes. |

|

|

|

I then completed the small parts

installation, such as flying/landing wires, tail brace wires. Trim drives,

pyro tubes and aileron spades. The prop/spinner was then installed and the

canopy bubble added.

The whole thing took about ten hours

from start to finish, keeping in mind that I have now built 9 kits by

Airshowmodels.com. and I’m very pleased with the product.

This model is recommended for most

modellers

Article and photos by: Barney Dunlevy

|

|

|

|

|

Construction Articles Table of Contents

|